A Step-by-Step Guide to the Bathtub Reglazing Process

Achieve professional-grade results on your own with our advanced pour-on enamel. It’s the top choice for DIY enthusiasts seeking a durable, flawless finish. Ready to take on the project? Let’s break down the process so you can reglaze with confidence.

Bathtub reglazing is a project that can be done by do-it-yourselfers. Kits and instructions are readily available for those willing to try. However, they do not always get the best results in terms of appearance and durability.

Why is that? Well, just like in any type of work, small details can make a big difference, and beginners don’t have the same level of knowledge and experience that professionals do.

In this article, we’ll go over the reglazing process and explain some of the details that can help you avoid mistakes and get a long-lasting, professional-looking finish, even if you’ve never reglazed a bathtub before.

Reglazing a bathtub yourself will save you about $150-200 in labor costs. That alone is motivation enough for some people to do it themselves, especially if they have a knack for handyman projects. For others, however, their motivation goes beyond just a monetary reward. They thrive on the feeling of accomplishment and take pride in successfully completing a new challenge,

Regardless of your motivation, let’s get into the nuts and bolts of the project.

Initial preparation

In order for the pour-on enamel to work properly, it must be at room temperature, so bring the material indoors the night before and let it set overnight before starting your project.

Before you begin, look around the room to assess the amount of work space available and especially the access to the bathtub. Remove as many objects and furnishings from the room as possible to simplify your work (bath mats and rugs, items on the edge of the tub, etc.). Remove the drain assembly if possible to prevent the pour-on material from running onto it.

Examine the walls and ceiling to ensure that they are free of dust, cobwebs, or peeling wall coverings (paint, wallpaper or plaster) that could possibly fall into the pour-on material while you are working. These could ruin the finish if the enamel hasn’t hardened.

If your tub has edging next to the wall (such as molding trim or a caulking strip), it will need to be removed. It’s best to replace it with new edging when the work is done and the glaze is dry to keep water from seeping into the space next to the wall.

Make sure you have the right Personal Protective Equipment. Pour-on enamel is a safe, eco-friendly product, but even so you should protect your skin from direct exposure. Use gloves to protect your hands and wear close-fitting, comfortable clothing that you don’t mind getting dirty or stained. When you’re working with liquid enamel you’ll inevitably get stains on your clothes, and it’s impossible to remove. Avoid loose-fitting clothing that could get in the way or brush against the finish and ruin it.

Don’t forget your shoes; they’ll likely get stained, too, so plan accordingly. Secure your hair or wear a head covering to prevent hairs from falling into the enamel. Also, when stripping the old enamel, wear a respirator to protect your airway and lungs.

Preparation of Materials and Tools

Gather all your materials and tools. In addition to the pour-on enamel itself, you’ll need a degreaser, clean lint-free rags, a spatula, masking tape, packing or duct tape, a utility knife, a hair dryer, and tools for cleaning the surface (to clean it either manually or with electric tools).

Keep your tools and supplies at the entrance to the bathroom. That way they will be within reach but out of the way so they won’t interfere with your work.

You will also need sandpaper for sanding the surface. The grade, or grit, of the sandpaper depends on the type of material the tub is made of.

The toughest abrasive, 50-60 grit, is suitable for steel bathtubs that have not been reglazed before. 40-60 grit is also used for steel and cast iron tubs that have previously been reglazed.

60-80 grit is a good choice for cast iron tubs that have not been reglazed before.

Plastic tubs are best sanded by hand using 100-120 grit sandpaper.

For steel and cast iron bathtubs, you can use an electric drill with a sanding disc. That will significantly speed up the process.

Removing the Old Paint

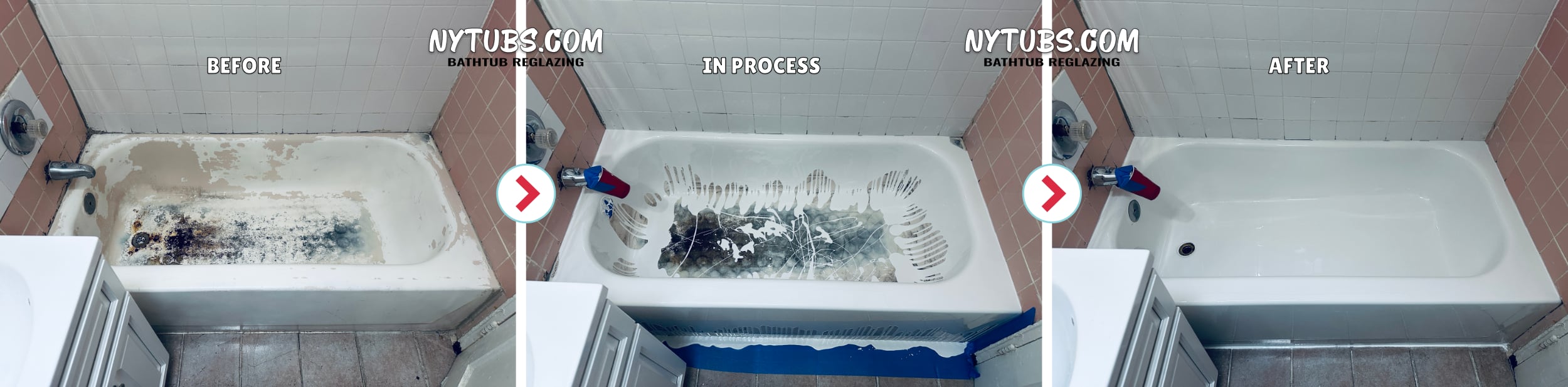

This step is the absolutely the most crucial to achieving a flawless, durable finish.

If the tub has previously been reglazed, the top layer must be removed completely to prevent the new coating from peeling or chipping.

Regardless of whether the tub has been previously reglazed, the surface of the tub must be smoothed to a matte, uniform finish without any chips or sharp edges.

Pay special attention to inaccessible areas such as where the tub meets the wall and the rounded surface inside the tub.

The best way to remove the old coating is to alternate moving the sander or sandpaper in side-to-side and up-and-down movements. Once the surface is clear of the coating, use circular movements to smooth it. If the removal is done with an electric tool, do the final smoothing by hand.

Surface Cleaning and Rinsing

At this point, remove the dust from all surfaces in the room and shake it from your clothes to avoid having it fall into the glaze or spread to the rest of the residence. Use a vacuum cleaner where possible or clean it up with a rag.

If there is a cloud of dust in the bathroom, turn on the hot water for a while and close the door. The steam will quickly remove the dust.

The final stage of cleaning is thoroughly washing the tub and rinsing it. If you use a detergent, make sure it is thoroughly rinsed so it does not leave a residue on the surface that could affect the adhesion of the pour-on enamel.

Drying

After cleaning and possibly steaming the bathroom, all moisture needs to be completely removed. Dry the tub and all adjacent surfaces with a lint-free cloth, or use a hair dryer.

Pay special attention to the corners where the tub meets the wall because water often accumulates there and can run down onto the finished coating.

Place a plastic bag around the spout and secure it tightly with packing tape or duct tape to prevent any drops of water from leaking into the tub.

Final Preparations

Mask off the tub edges where they meet the wall. If the drain cannot be removed, protect it with specialized masking paper and painter’s tape. Cover the floor with heavy-duty masking paper or drop cloths to ensure complete protection from any material drips during the process.

The last step in preparing the surface is to degrease it. Pour 91% Isopropyl Alcohol on a lint-free rag and wipe the entire surface of the tub. Remove your gloves and with your bare hands, go over the entire surface and collect any small debris or lint that remains so it will not affect the adhesion or appearance of the coating.

Material Preparation

With the materials at room temperature, you can now prepare the mixture. Start by pouring the hardener into a bucket of enamel and mix thoroughly. A 2 inch flat spatula works well for mixing.

To blend it completely, make sure to mix in a circular motion, scraping down the sides and bottom of the container. Do not mix too vigorously or use a drill because this can cause bubbles that will appear when you pour the mixture on the surface of the tub.

Follow the manufacturer’s instructions carefully regarding how long to stir the mixture. Do not try to “eyeball it”; set a timer to make sure you spend the required amount of time mixing it.

Let the mixture set for 5-10 minutes. While you’re waiting, prepare a small plastic container for applying the pour-on enamel.

Application of the Material

Place the bucket of enamel in the bottom of the tub and dip some out into the small plastic container. Start pouring it on the upper edges of the tub in an even stream around the perimeter, moving from left to right until you have covered the edges completely.

Next, start covering the side walls of the tub. This will be done in two rounds, again working from left to right around the tub. Cover the top half of the tub walls on the first round.

Make a second round to cover the bottom half of the tub walls, following the same procedure.

Watch for excess material that runs toward the drain. If this happens, scrape it away with a spatula to prevent a build-up around the drain.

Finally, pour the remaining enamel directly from the bucket into the bottom of the bathtub and level it by spreading it with a spatula in a criss-cross pattern. The excess material will run toward the drain, and the surface will self-level in about 10-15 minutes.

If any pour-on material has dripped outside the tub, remove it before it hardens. You can use a rag or a spatula for this. Repeat again twice at intervals of 10-15 minutes, because the material may continue to flow before it dries.

Congratulations! You’ve successfully finished reglazing your bathtub. Now you just need to wait about 24 hours (or the time suggested by the manufacturer) for your tub to dry completely. Then you can reattach the drain assembly and reinstall the corner molding, and your like-new tub is ready to enjoy.

However, if after reading this you’re overwhelmed by the task, call New York Tubs. Our professional technicians have been doing this for years, and they know all the ins and outs of bathtub refinishing. They can reglaze your tub from start to finish in just 3-4 hours, and you can sit back and relax, knowing that everything is in the hands of our knowledgeable, experienced craftsmen.

Artem Tugbaev

Artem Tugbaev