Bathtub Reglazing in Staten Island, NY

New York Tubs provides expert bathtub reglazing in Staten Island. Our signature pour-on method delivers a high-impact, premium finish at a fraction of the cost of replacement. Save time and restore your tub with a durable, modern formula proven to last for years.

More Than Just a Cosmetic Upgrade

Bathtub refinishing is a spectacular upgrade to even those tubs that seem hopelessly damaged. The pour-on material covers any cosmetic defects with a dense snow-white layer, as well as fills in and restores all violations of the surface integrity.

The Hidden Problems in an Old Bathtub

A tub that has been used for many years may not only have traces of ingrained rust, rough areas and a network of cracks on the enamel layer.

In addition to these visual flaws, chipped and detached enamel can appear, as well as deep cracks, which not only spoil the appearance of the bathtub and in general the bathrooms, but also are a favorable environment for the development of microorganisms. The sharp edges of peeling enamel can cause cuts as well.

Our Flawless Solution: The Pour-On Method

If you see your bathtub in this unattractive description, then it is time to reglaze it with the pour-on method. The old surface with all its defects will disappear without a trace, giving way to a perfect sparkling whiteness and smoothness.

Bathtub reglazing with an advanced pour-on material is suitable for tubs of any configuration and size. This material covers surfaces with any relief due to its fluid, plastic consistency.

Evenly distributed over the prepared bathtub surface, the material forms a strong, uniform, smooth layer that is firmly held onto the surface of the bath due to its good adhesion.

A Durable Finish You Can Trust

This property determines the durability of the coating, which is created by specialists in the reglazing of tubs using pour-on application method.

Frequently Asked Questions

What is bathtub reglazing?

Is refinishing better than replacing my tub?

What material is used?

How long does the reglazing process take?

The material requires about 24 hours to fully dry and harden before you can use your “new” bathtub.

- Minimal mess and disruption to your daily routine.

- Experienced professionals ensure a clean workspace.

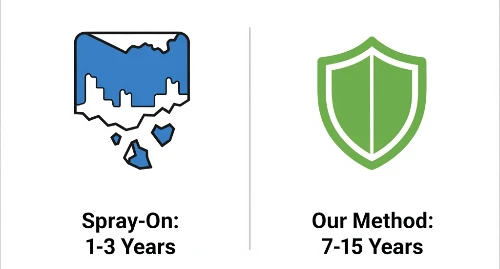

How long does the reglazed finish last?

Our advanced pour-on method creates a thick, durable bond that lasts several times longer than inferior spray-on paints and is highly resistant to peeling and chipping. Following our simple care instructions is the key to maximizing its lifespan.

- Premium Pour-On Method

- Ready in 24 hours

- Odorless

- Premium Pour-On Method

- Ready in 24 hours

- Odorless

- Premium Pour-On Method

- Ready in 24 hours

- Odorless

Additional Services

| SERVICE | COST |

|

|

Free with bathtub service |

|

|

Travel fee for certain areas (e.g., Manhattan $25–$60). |

Why the Pour-On Method Wins — Every Time

Our premium Pour-On Method provides far greater long-term value and a healthier, odor-free experience. Here's why:

| CRITERIA | Traditional Spray-On Method | Pour-On Application (Our Method) |

| Lifespan | 1-3 years | |

| On-Site Work Time | ~5 hours | |

| Thickness | 1/160 = 0.15mm | |

| Fumes & Odor | Strong, lingering chemical odor | |

| Toxicity (VOCs) | High | |

| Safety | Requires vacating the home | |

| Ready to Use | ~48 Hours | |

| Long-Term Value | Lower initial cost, requires frequent re-application | Lasts up to 5x longer, better investment |

Bathtubs, shower bases, sinks made of any materials can be repaired by the pouring method. It can be used equally successfully on cast-iron enameled products, as well as on plastic or any other ones.

The process does not take much time. To date, this is the fastest and most convenient way to repair or resurface plumbing. Works are carried out on the installed bath for about 3-4 hours without dismantling. The material which does not have a sharp smell will not inconvenience the apartment’s residents, and it will be possible to resume usage of the bathtub within the next 24 hours.

The hardened coating, provided that it was made by a qualified craftsman and high-quality materials, gains strength, reliability and resistance to damage. This allows you to extend the life of the tub, delaying its replacement for the next 15 years.

Gallery of Our Transformations

REVIEWS

Our responsive, friendly service and time-tested superior product set us apart in the industry. But don’t just take our word for it—listen to what our clients have to say:

Follow us on Instagram

Meet our team of Bathtub Refinishing Specialists in New York:

Service areas in Staten Island:

- Annadale

- Arden Heights

- Arlington

- Arrochar

- Bay Terrace

- Bloomfield

- Brighton Heights

- Bulls Head

- Castleton Corners

- Charleston

- Clifton

- Dongan Hills

- Egbertville

- Elm Park

- Eltingville

- Emerson Hill

- Graniteville

- Grasmere

- Great Kills

- Heartland Village

- Huguenot

- Lighthouse Hill

- Manor Heights

- Mariners Harbor

- Meiers Corners

- Mid Island

- Midland Beach

- New Brighton

- New Dorp

- New Springville

- Oakwood

- Old Town

- Pleasant Plains

- Port Richmond

- Prince’s Bay

- Randall Manor

- Richmond

- Rosebank

- Rossville

- Saint George

- Shore Acres

- Silver Lake

- Stapleton

- Sunnyside

- Todt Hill

- Tompkinsville

- Tottenville

- Travis – Chelsea

- Westerleigh

- Woodrow

- and more…

-

Special Limited Time Offer14

days 13

hours 48

minutes -

To Get an Estimate or to Schedule Work